VAE is a flexible and sustainable polymer. Current VAE’s are already available as a 50% biobased version, as the industry is already sourcing bio acetic acid. Acetic acid is a building block for VAM (together with Ethylene). VAE is made by VAM and Ethylene.

Technically, VAE’s could be made of BIO-VAM (bio-ethylene + bio-Acetic-acid) & bio-ethylene. For now, the industry practically is not ready, rather the source of bio-ethylene is to expensive, or the industry downstream is not yet ready to pay for a 100% biobased product. But times will change, in the future, approx 00% biobased VAE will probably will be available.

So what is VAE?

VAE (Vinyl Acetate Ethylene) is a copolymer that is made by copolymerizing vinyl acetate and ethylene monomers. It is a type of thermoplastic polymer that is commonly used in various applications such as adhesives, coatings, and films. VAE has a soft, rubbery consistency and is known for its good film-forming properties, flexibility, and strong adhesion to a variety of surfaces. It is also resistant to moisture and has good chemical stability. The properties of VAE make it useful in a variety of industries, including construction, packaging, and textiles.

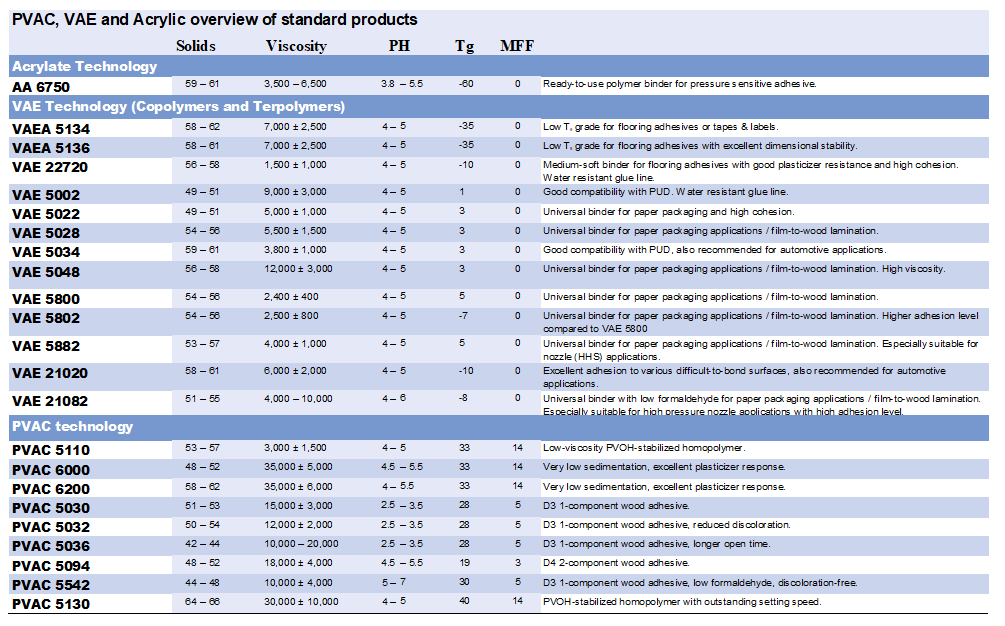

VAE’s are practically available with Tg from -10°C to +40°C. Special versions, with acrylate, are even going to -35°C

What is glass transition temperature

Glass transition temperature (Tg) is the temperature at which a material, commonly an amorphous solid, undergoes a change in its properties due to a transition from a solid-like state to a more viscous or rubbery state. At the Tg, the material experiences a change in its glass transition, where its thermodynamic and mechanical properties change, leading to a reduction in its rigidity, and an increase in its ductility and viscosity.