Styrene butadiene is a synthetic copolymer made of the monomers styrene and butadiene. It is made in atmosperic reactors. SB/SBR is used in a wide range of applications, including car tires, shoe soles and heels, drive couplings, automotive parts, mechanical rubber goods, wire insulation and cabling, belting, roll coverings, haul-off pads, hoses, seals, gaskets, abrasion resistance and metal adhesion. Styrene Butadiene is also used as a binder in lithium-ion battery electrodes, for carpets and many other adhesive applications..

Thermoplasticity

SBR is not a thermoplastic elastomer. It is a synthetic rubber derived from styrene and butadiene. Thermoplastic elastomers are a class of copolymers that exhibit both thermoplastic and elastomeric properties. Styrene-butadiene block copolymer (SBS) is an example of a thermoplastic elastomer that is derived from the same monomers as SBR. SBS is a triblock copolymer based on styrene-butadiene, with characteristics of plastic and rubber.

Thermoplastic alternative

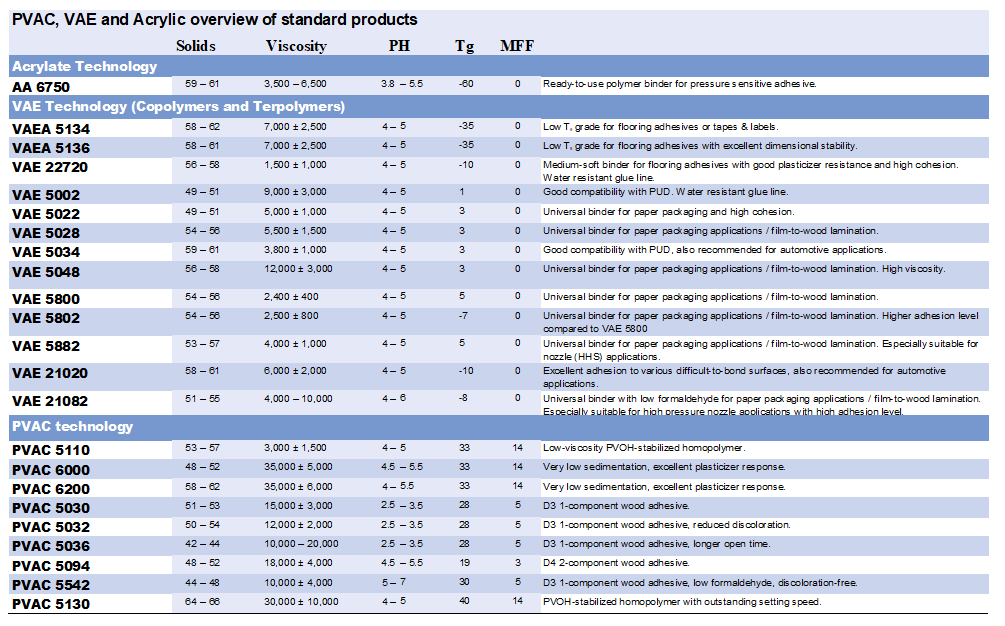

An alternative thermoplastic polymer for adhesive and coating applications might be VAE (Vinyl Acetate Ethylene). VAE is a thermoplastic polymer with a relatively high temperature resistance of approximately 110°C. VAE is the Ethylene copolymer, plasticized version of PVAC and is used in various applications such as coatings, adhesives, and binders. VAE is not the same as EVA (Ethylene Vinyl Acetate), which is also a thermoplastic polymer used for making hot melt adhesives. VAE is typical a dispersion in water, and also available as water solluble additive for cementious adhesives and other construction applications.

Recycling and seperation of Styrene butadiene polymers

Styrene butadiene adhesives and coatings are known for it’s high water resistance, allthough not being a very stable polymer when exposed to sunlight. For recycling purposes, polymer like VAE have better properties. VAE polymers can be water solluble (although water resistant versions are possible with Crosslinking agents). And VAE polymers are even better solluble in light solvents. Therefor, products assembled with VAE, like carpets and artificial grass, can be better seperated into single materials when it’s end of life is reached for mechanical or chemical recycling.